Technology

Brand | Technology

trigalight is a unique self-powered illumination technology with the world's smallest gaseous tritium light sources (GTLS) that delivers constant luminescence for decades without any external energy source. With trigalight mb-microtec ag offers a maintenance-free, very compact system with a minimal installation size, which stands for safety and efficiency. A trigalight consists of a glass capillary, the inside of which is coated with a luminescent powder (zinc sulphide) and filled with tritium gas. The glass capillaries are available in different colours, shapes and sizes. Their smallest possible outer diameter is currently 0.30 mm, so-called hairlights.

trigalight works similar to a cathode ray tube, which was once used in television screens. The luminescent coating (zinc sulphide) on the inside of the glass capillaries has the ability to transform the kinetic energy of the electrons into light. The energy is generated by the added tritium gas. The tritium nucleus slowly decays, emitting electrons in the process. When the electrons hit the coating, energy in the form of light is emitted. The colour variations of trigalight depend on the diversity of coatings. The luminescence of the light sources is proportional to the filling pressure (quantity of gas).

Production Process

Various machines required for the production process are developed in-house by mb-microtec ag.

PRODUCTION OF GLASS CAPILLARIES

Large glass tubes are heated and dawn into thin glass capillaries of the desired dimension. The smallest possible outer diameter is 0.30 mm and is equivalent to approximately five times the thickness of a human hair.

COATING PROCESS

The inside of the glass capillary is coated with a luminescent powder (zinc sulphide). Any colour is possible. The colour green is most often used, as it is the brightest colour perceived by the human eye.

TRITIUM FILLING

The glass capillaries are filled with tritium gas in a process developed by mb-microtec.

LASER CUTTING PROCESS

The glass capillaries filled with tritium gas are cut to the desired length and at the same time hermetically sealed by a highly automated laser.

QUALITY CONTROL

Each individual light source is subjected to a strict quality and leak test.

APPLICATIONS

Depending on the application, the light sources are installed in aluminium or polymer sleeves with sapphire glass or fitted directly onto dials. Our trigalight products are mainly used in the tactical, watch, security, automotive, aerospace and aeronautical industries.

Did you know that...

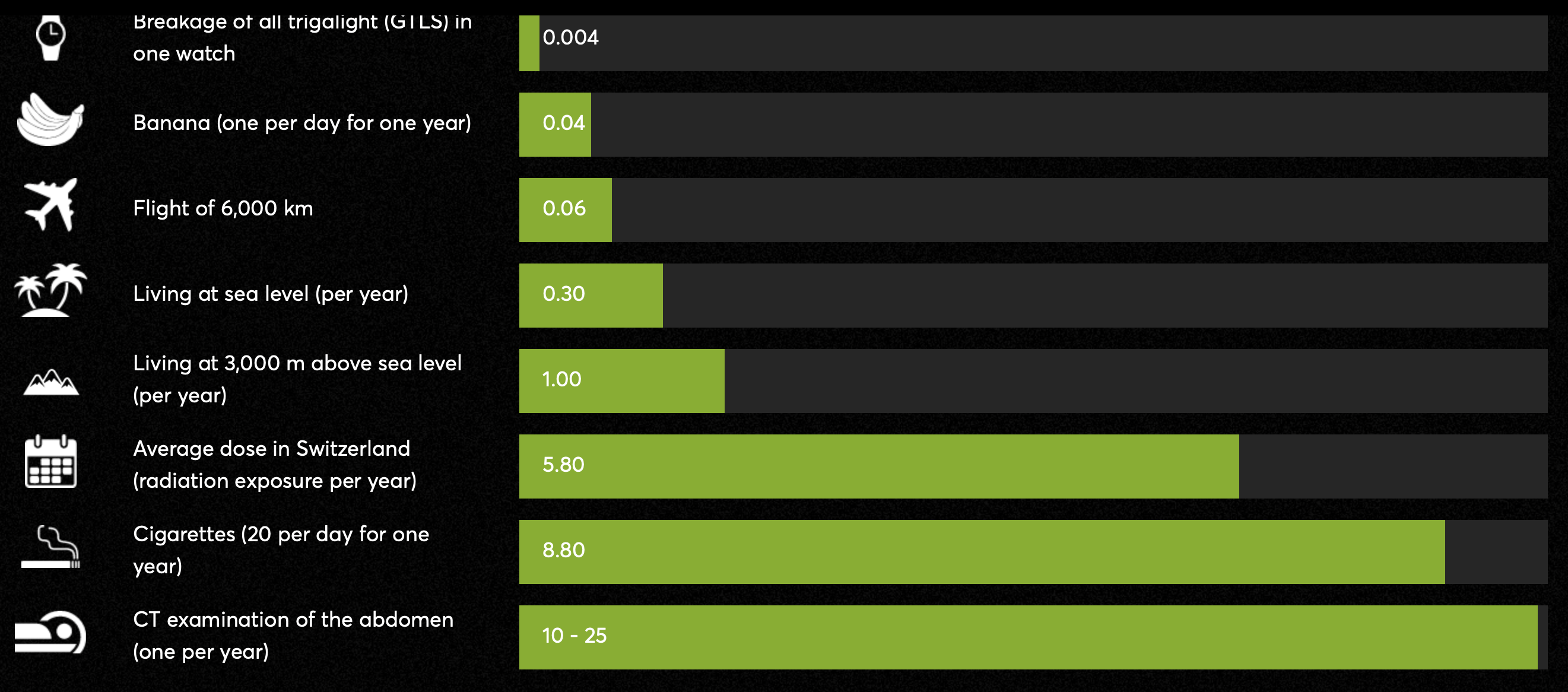

Tritium is a natural trace isotope of hydrogen. Its nucleus, also called a triton, consists of a proton and two neutrons. Tritium is a radioactive beta emitter with a half-life of 12.32 years and decays by sending out an electron. In its natural form, tritium is most commonly found in the stratosphere, but it is also created as a by-product in nuclear fission or in the cooling water of reactors. Tritium is a soft beta emitter, i.e. the energy of the electrons is very low. In water, it is stopped after a few micrometres, and can not penetrate the outer skin layers. As a result, trigalight does not emit any harmful radiation, because the electrons cannot pass through the hermetically sealed glass capillaries.