Briefing

The technology is developing rapidly worldwide but the number of tritium applications remains relatively constant. Therefore, the main focus for trigalight is looking for new application fields and new markets to develop. As secondary focus, the production process needed for the trigalights is very complex and could also find further applications in the market. The self-made capillaries are also a by-product of the trigalights that could be used as an idea base for numerous applications.

Trigalights are typically used to illuminate things in applications where there's no space for any external power source. The applications usually also include actions that need to be carried out in dark environments or in emergency situations (e.g., like reading time on a watch dial or operating a safety-relevant item). Thinking of such typical situations that occur in darkness may help to find new applications for trigalight technology. If using an external power source (such as a battery) for illumination purposes is an overkill or simply not possible due to size, trigalight might be a perfect solution as well…

Please be aware that trigalights glow with a very low intensity and cannot be used e.g. to illuminate a whole room.

Content of contribution

The submitted idea should answer the following questions:

- What is the problem that the application solves?

- What is the benefit of the application?

- What does the solution approach look like?

- What other solutions of the problem already exist and how does the submitted idea stand out from them?

Current applications of the product

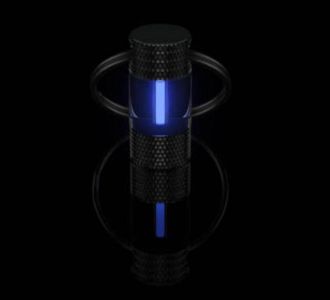

Watch illumination hour hand/minute hand/second hand/indices/marks/design

|

Outdoor equipment like compasses, knives, and equipment markers. |

|

|

|

Tactical iron sight illumination as front and rear sight. Trigalights are encapsulated as inserts. Often trigalights are combined with daylight fibers. Aerospace and aeronautical industries, as illumination of dials, monitors, and measuring devices.

|

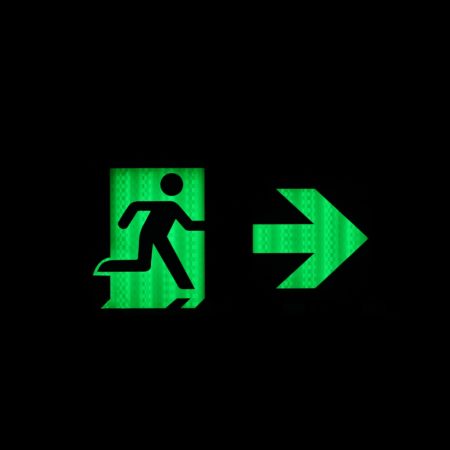

Escape route and exit signs illumination. |

|

Unique selling points

In most of these applications, the unique selling points play a major role so that other technologies cannot compete with trigalights.

USP's (Unique Sales Points):

- SWISS MADE

- In-house–developed self-powered illumination technology.

- Compact and robust design

- Smallest tritium gaseous light source Ø0.3mm

- Requires no external energy source

- Delivers luminescence for decades

- Temperature-resistant -67 to 392° Fahrenheit (-55 to 200° Celsius)

- 10 years light guarantee

- Maintenance-free

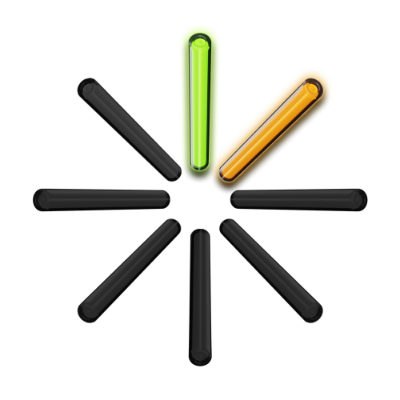

- Selection of different colors, shapes, and sizes

Product Properties

The different applications are feasible thanks to the many other different properties of trigalights:

Laser sealed trigalights:

Our trigalight are available in a great diversity of standard colours. You can choose between green, yellow, white, ice blue, pink, violet, orange, red and blue. The smallest size – our hairlights (0.30 mm) – are available in green, yellow and ice blue.

The standard cross-sectional shape is round. Our trigalight are also available in square or rectangular form.

Our round light sources are usually produced with an outer diameter of 0.30 mm to 3.00 mm and a length of 1.30 mm to 25.00 mm. The rectangular light sources are available with a standard cross section of 1.00 mm to 4.10 mm x 0.75 mm to 1.50 mm and a length of 3.00 mm to 25.00 mm.

Arcs and Spheres

Hand sealed bench made trigalights:

Our arcs and spheres are available in green and orange as standard.

Our arcs are normally manufactured in round or rectangular cross-sectional form.

The round arcs are usually produced with an outer diameter of 4.00 mm, an arc dimension of 4° to 174° and a radius of 13.20 mm to 32.00 mm. Our rectangular arcs are produced with a standard cross section of 4.10 mm x 2.30 mm, an arc dimension of 180° and a radius of 10.80 mm. The spheres are available with an outer diameter of 15.00 mm as standard.